Gore provides the defence sector with solutions that are reliable, remain in service longer and require less maintenance.

Defence Products

Avionics aboard military aircrafts are designed to be more than the eyes and ears of the pilot. In addition to tasks like communication, navigation, monitoring, air flight control systems andor weather radar, avionics need to give the pilot a decisive edge in hostile environments. The reliability and accuracy of these systems are non-negotiable.

Improvements in the aerospace industry lead to the need for more power performance and signal capacity. The ability to be updated for further enhancement has to be factored in.

Also, lighter-weight materials are growing in priority as a means to save costs related to fuel burn.

Cables are the lifelines of electronic systems, ensuring reliable and accurate communication, both onboard and with external communication systems. While continuously moving through tight areas in the aircraft, cables can easily be compromised by abrasion. Other stress factors include harsh contaminants like fuels, oils and chemicals and extreme temperature changes. Damaged insulation can lead to failures over time, resulting in cost-intensive downtime and maintenance.

Performing under the most testing conditions

Gore maintains global testing facilities to evaluate the performance of our products and increase our understanding of their reliability in the field. Delivering three areas of expertise — digital and microwave signal analysis, environmental and stress testing, and electromagnetic compatibility — we optimise electrical signal integrity and other important parameters for our electronic products.

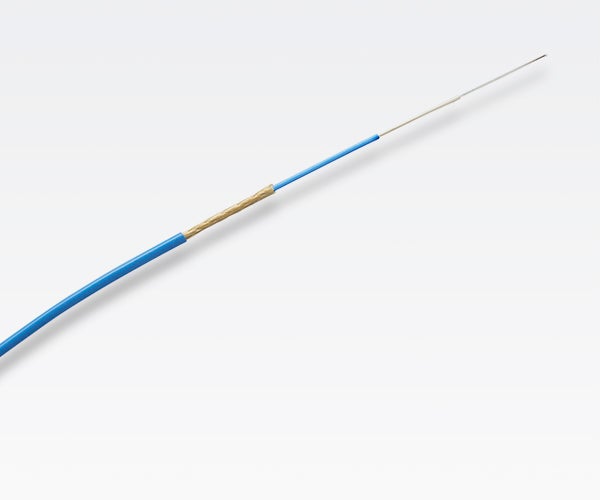

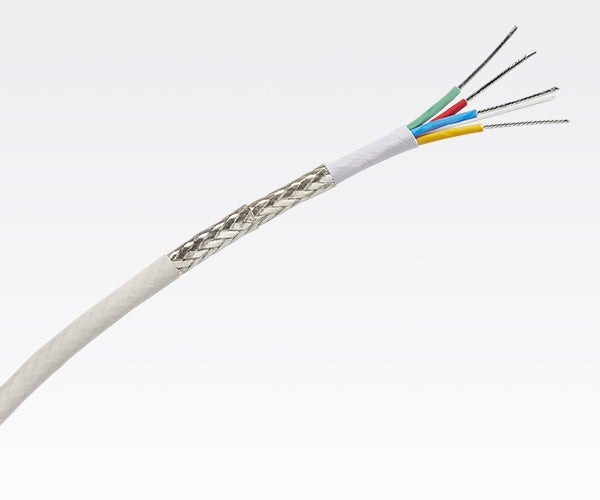

Our cables are engineered with a robust insulation that withstands the mechanical, electrical and environmental stress of flight operations. The cables are abrasion-resistant and flexible, allowing them to be routed easily during installation. During use, they provide excellent signal transmission with optimal shielding and low skew. Our cables are constructed with ePTFE and demonstrate its special characteristics, keeping our cables from reacting to the broad temperature ranges and contaminants used in an aircraft.

In a cost-sensitive environment, maintenance, repair and overhaul criteria are essential to reduce life-cycle costs and increase affordability.

Cables and materials need to be smaller and lighter weight as each additional pound of weight can increase operating costs. At Gore, we're careful that our fluoropolymer technologies deliver solutions that are significantly smaller with thinner insulation. Some of them are up to 60% lighter compared to the industry standards — while providing the same amount of power performance and protection that the defence industry requires.

From the Cockpit to the Tail

Gore’s track record in the aerospace defence industry dates to in 1958, when we prototyped designs of fluorocarbon-insulated wires and ribbon cables for use in military aircraft. Since then, our product portfolio has expanded significantly to meet the current and future needs of the industry. Today, our products seal against moisture and corrosion, enable power and signal transmission, and ensure all electronically powered systems work reliably. We are proud that GORE® Aerospace Cables and Materials, EMI shielding materials (U.S. site), and aircraft sealants (U.S. site) have featured in every major military aircraft, including the latest fifth-generation fighter aircraft, the F-35.

Aerospace Materials

Maintenance personnel use our GORE™ Skyflex™ Aerospace Materials (U.S. site), including sealant tapes and gaskets, to protect aircraft panels, fuel tanks, floorboards and windshields from moisture and corrosion. Aircraft downtime can thus be significantly reduced.

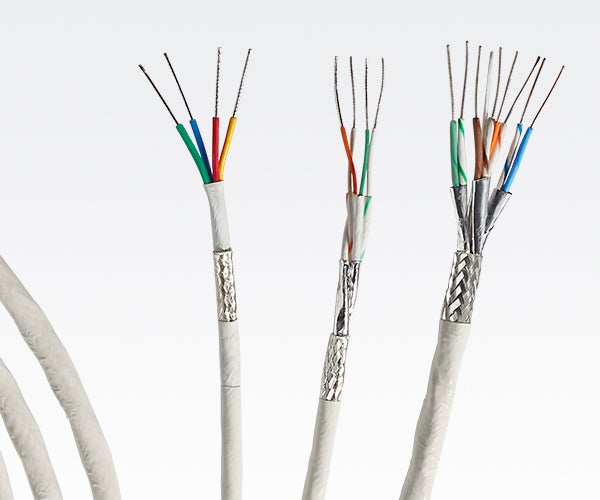

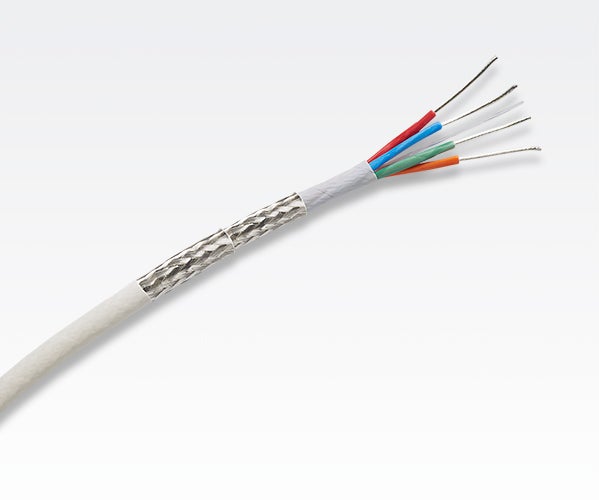

Cables and Cable Assemblies

Smaller, lighter-weight cables and cable assemblies ensure that systems talk to each other, data are transferred, and power gets transmitted.

Gore hybrid round cable assemblies deliver high electrical and mechanical performance, and they meet the international requirements of GORE® MIL-STD-1760 Aircraft/Store Electrical Interconnection System. These GORE® MIL-STD-1760 Assemblies ensure the operation and employment of stores within many of today’s airborne platforms and define a complex arrangement of interfacing signals. While GORE® Shielded Twisted Pair Cables and GORE® Ethernet Cables transmit high-speed data — for instance, for avionics electronics or digital video systems — GORE® Optimized Coaxial Cables can be mainly found in navigation systems. GORE® Fibre Channel Assemblies transmit signals and GORE® Cableband Systems take care of providing power where power is needed.

All our these products provide a reduction in aircraft weight and simplify routing while delivering electrical and mechanical integrity in the most challenging applications.

EMI Shielding

Shielding to control EMI (electromagnetic interference) is a staple in modern electronics, playing a major role in military applications. With myriad systems onboard, including sensitive electronic equipment, signals may interfere with each other. Also, without adequate shielding, external sources may affect the function of board electronics.

EMI shielding materials from Gore ensure signal integrity, making sure all devices work reliably. GORE® Fibre Channel Assemblies, which are also equipped with an EMI suppression, also help to reduce the risk of interference.

Microwave Cable Assemblies

Our microwave Cable Assemblies enable pilots and other flight personnel to better scan for threats being applied in airborne electronic surveillance, various warning systems, and in navigation and communication systems. Gore-Flight™ Microwave Assemblies are a fit-and-forget solution that provide durability and a lightweight construction.

Contact Us

UK

+44 1382 56 1511

+44 1382 56 1007 (fax)

United States

+1 800 356 4622

Germany

+49 9144 6010

+49 9144 6816 (fax)

Italy

+39 045 6209 209

+39 045 6209 165 (fax)

France

+33 1 5695 6565

+33 1 5695 6401 (fax)

Spain

+34 93 480 6900

+34 93 373 7850 (fax)

Sweden

+46 31 7067800

+46 31 864226 (fax)

China (Beijing)

+86 10 5707 4999

+86 10 5707 4900 (fax)

China (Shanghai)

+86 21 5172 8299

+86 21 6247 9199 (fax)

China (Shenzhen)

+86 755 8359 8262

+86 755 8359 1654 (fax)

South Korea

+82 2 393 3411

+82 2 393 1285 (fax)

Japan

+81 3 6746 2582

+81 3 6746 2571 (fax)