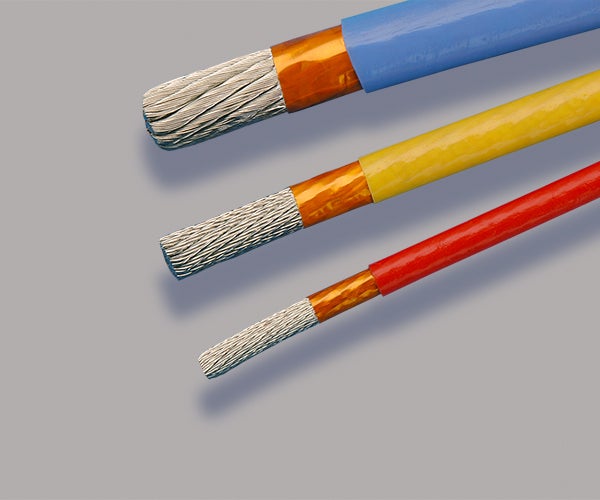

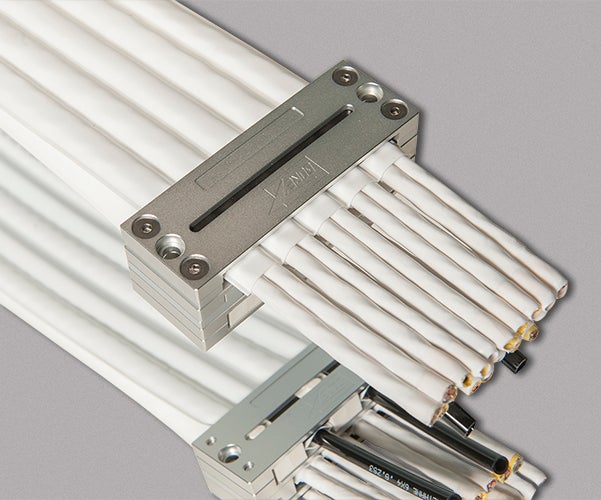

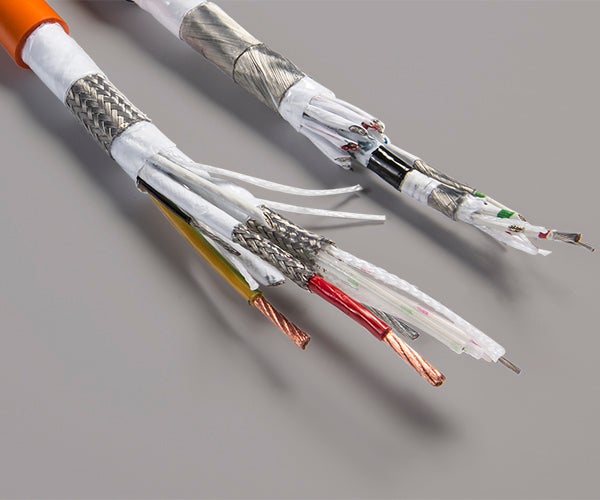

Type SPP for High-Current Applications

Aboard spacecrafts, power-generating systems rely on their cables — and, therefore, so do space missions. GORE Space Cables, Type SPP for high-current applications are highly reliable, and their robust design is small, lightweight and flexible with a tight bend radius for easy installation in tight spaces.

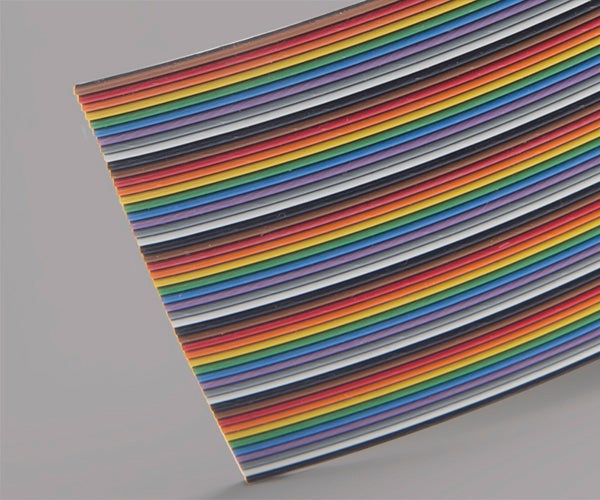

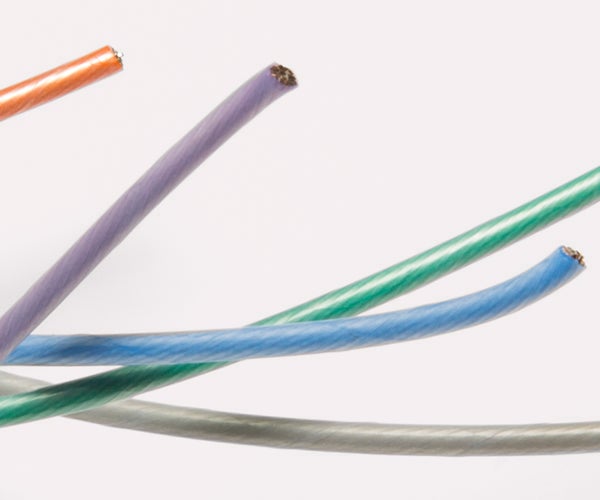

Color-Coded IDC Ribbon Cables

With industry-standard color coding on each conductor, GORE Color-Coded IDC Ribbon Cables provide accurate and discrete wire termination to prevent interference. And with their PTFE insulation, the cables are resistance to chemicals, extreme temperatures and aging.

IDC Ribbon Cables: GTX602 Series

In high-heat applications like soldering, field repairs and petroleum processing, some cables could burn, degrade or react to chemicals, GORE IDC Ribbon Cables: GTX602 Series withstand temperatures up to 250° — while resisting aging — providing performance that can stand the heat, every time.

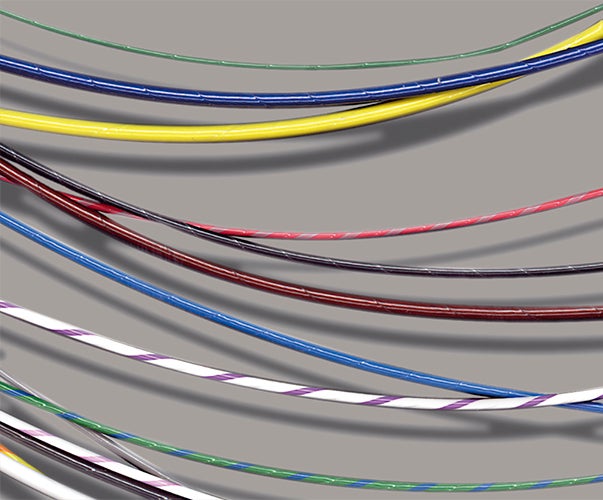

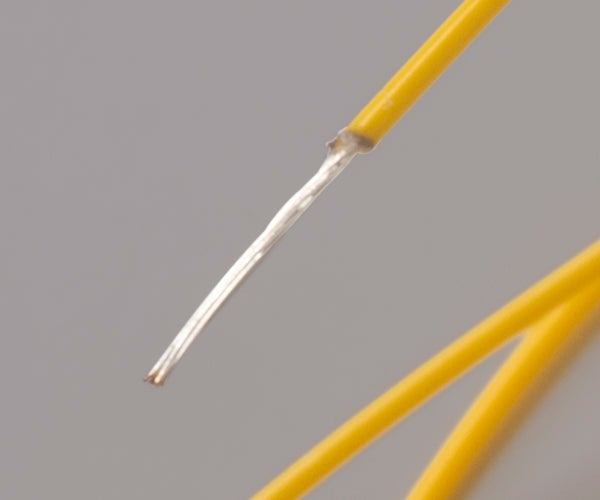

Hook-Up Wires for Oil and Gas Downhole Equipment

In harsh oil and gas environments, downhole tools need to handle mechanical stress — and, above all, not fail. The small size and robustness of GORE Hook-Up Wires make them tough and dependable, while providing design freedom to manufacturers.

MIL-W-81822/1A Hook-up Wire

Gore’s thin-wall technology provides greater abrasion and cut-through resistance for outstanding mechanical protection in harsh aerospace conditions. Whether your function is power or signal, our MIL-W-81822/1A hook-up wires deliver excellent electrical and mechanical performance in a small, lightweight and flexible package that meets or exceeds civil and military specification requirements.

PTFE Hook-up Wire

Engineered with specialized insulation materials, Gore’s wires deliver reliable electrical and mechanical performance in demanding aerospace environments including extreme temperatures and rigorous installation. Whether your function is power or signal, our PTFE hook-up wires provide added durability in a small, lightweight and flexible package while meeting stringent civil and military specifications.

Trackless High Flex Cable

Gore’s self-supporting cables eliminate the need for a cable track or chain completely for a more simple cable management system. Our trackless cables solve many challenges associated with particulation, vibration, size and weight. They provide increased positioning accuracy, faster speeds, quieter motion, reliable installation and cleaner operation.

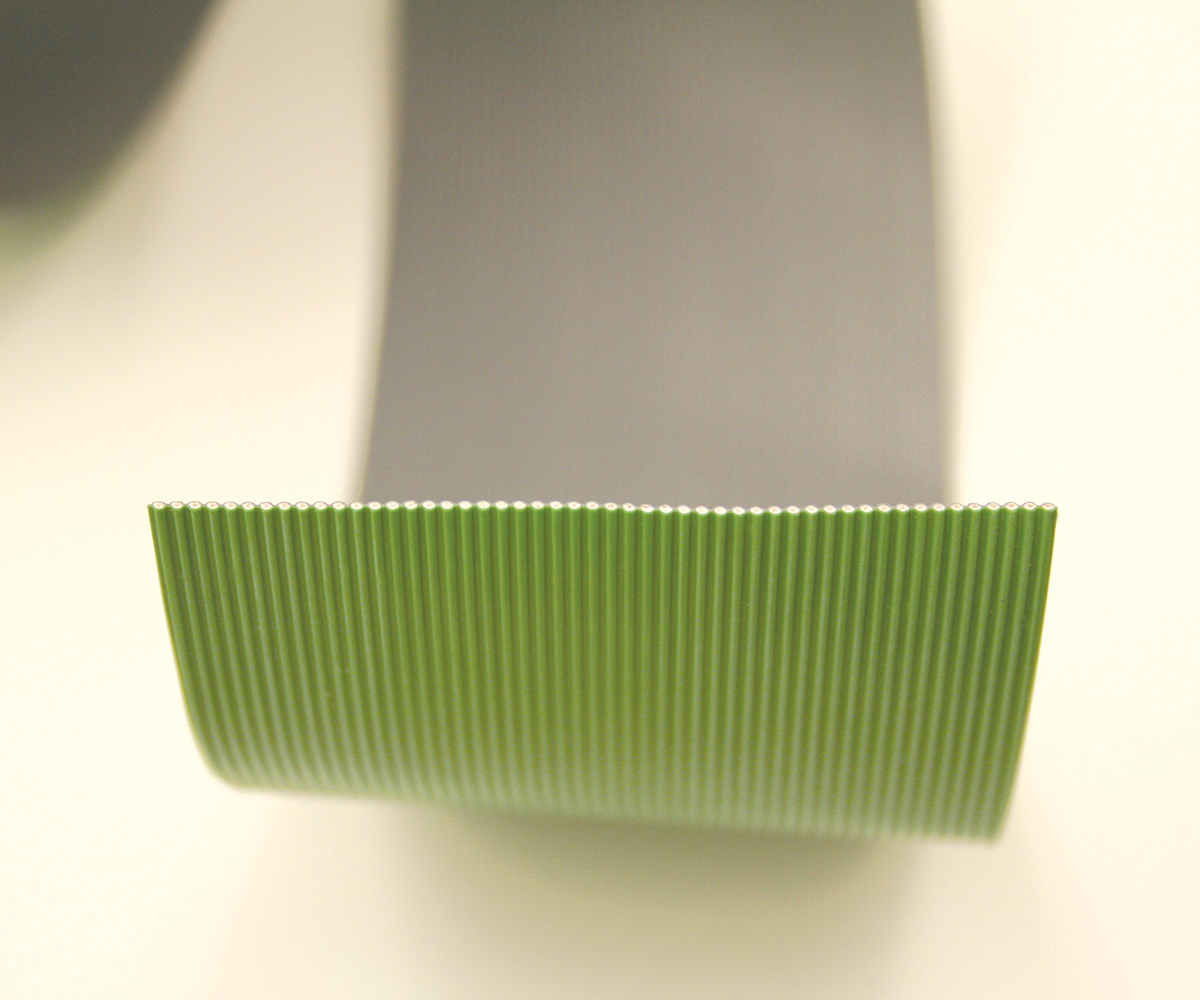

IDC High Flex Ribbon Cables

In high-speed, continuous-flex applications, some cables may degrade or fatigue because of continuous abrasion in high temperatures. With a robust yet flexible construction, GORE IDC High Flex Ribbon Cables remain reliable after continuous use.

Round Cable For High Flex Applications - Custom Solutions

Gore’s cables deliver excellent electrical, mechanical and environmental performance in complex automation environments. With a proven flex life, our cables can be reliably used in applications where other cables fail. They deliver long-lasting results for reduced downtime, maintenance and equipment lifecycle costs compared to standard round cables.

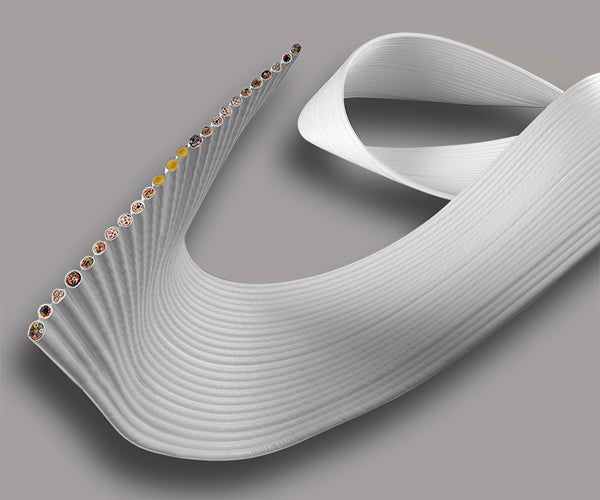

High Flex Flat Cable

With a proven flex life, Gore’s lightweight cables improve signal integrity, reduce particulation, and can be reliably used in any energy chain or cable track. They provide a simple cable management system in complex environments where other cables fail — ultimately reducing downtime, maintenance and total costs over time.