As semiconductors geometries get smaller, the need for process purity grows. Gore delivers gaskets, filters and cables to keep this process pure, along with new developments in EUV lithography to help manufacturers prepare for the future.

Semiconductor & Microelectronics Products

Overview

How “micro” can a microchip get? Over the decades, as microchips in smartphones, laptops, LED screens and other electronics have become smaller, manufacturers in the technology industry have pushed the limits of smallness in semiconductors. Semiconductor line-widths have been squeezed from the micrometre to nanometre range, while still delivering greater processing power and memory. A nanometre is one billionth of a metre—so small that it would take 100,000 nanometres lined up side-by-side to equal the diameter of a human hair.

This is the basis of Moore’s Law, which states that the number of transistors in a tightly packed circuit will double every two years. Gordon E. Moore made this bold claim in 1965, and for a very long time, it held true.

But can Moore’s Law keep going? Two issues may be slowing it down: the high cost of producing ever-smaller yet ever-more-powerful semiconductors, and the need for purity when manufacturing and processing them. These microscopic semiconductors could be contaminated by very small particles that could cause water defects; such defects could reduce yield and require costly maintenance time.

In short: As the size of semiconductor line-widths go down, production costs and the challenge of purity go up.

Gore is a longtime partner to technology companies navigating these challenges. We provide high-flow filters, microfiltration media, cables and various shielding solutions that keep processes seamless and secure. Our PTFE-based materials are chemically inert and durable, delivering the unquestionable purity that semiconductor manufacturers require.

The industry depends on fluoropolymers, like PTFE, for cleanliness and chemical compatibility. As semiconductors shrink further, manufacturers will need help innovating with PTFE membranes to make their microchips smarter, faster, smaller—and Gore has found ways to do it.

Looking Ahead: Cables for EUV Lithography

The next “big” thing for semiconductors is extreme ultraviolet (EUV) lithography, a process of carving more electric circuits into semiconductor wafers. In a lithography system, light transfers images onto silicon, similar to a camera that uses light to transfer images onto film. EUV lithography is considered the future of the computer chip; it produces a shorter wavelength that allows more electric circuits to be squeezed onto a chip.

Although the semiconductor industry still needs to iron out some challenges posed by this new method, Gore is taking the long-term view. In 2009, an optical systems manufacturer commissioned Gore as a long-term partner to provide the right cable assemblies for the ultra-high vacuum, low-pressure and ultra-clean environment that EUV lithography systems must operate in.

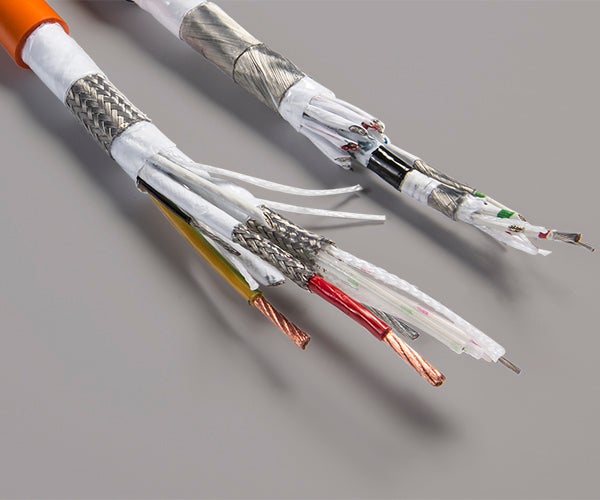

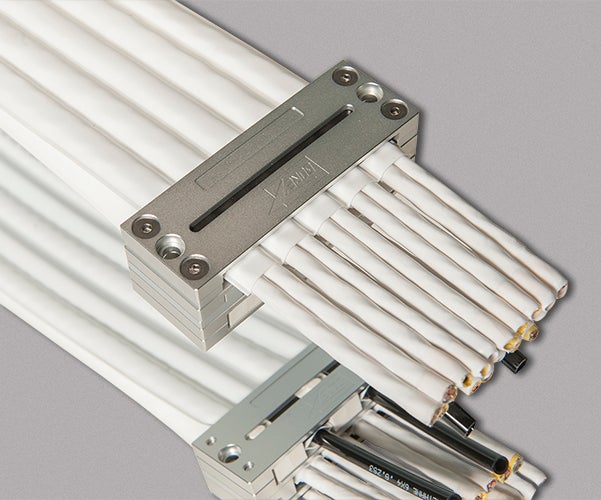

Because we invested early in developing cable connectors for the new EUV process we’re prepared to assist manufacturers as they adopt the new method. GORE® Cables reduce particulation and improve system performance and yield; non-shedding and chemically-inert versions are specially designed for cleanroom use. Our new line of cable assemblies for EUV lithography is marked by a low outgassing rate, which prevents them from emitting gases that could condense and contaminate a computer chip in an ultra-high vacuum environment. This quality in our cables makes Gore one of the few companies in the market who can clean and test our products for EUV lithography.

Even for manufacturers not yet ready to embrace EUV lithography, Gore provides a range of cables delivering high performance and purity, including high-flex, high data rate and microwave/RF cables for processing equipment, test and measurement, and integration.

A Portfolio Based on Purity

Due to semiconductors’ microscopic size, even the smallest hint of contamination can impair how they perform.

Gore’s materials keep semiconductor processing pure. With their PTFE base, our materials are chemically inert, have extreme temperature ranges, and are durable in use. Typically smaller and lighter than competitors’ materials, ours are known to increase process yields and reduce downtime — and, potentially, costs.

Along with our cables and cables assemblies, we provide:

- microfiltration media, offered in both membrane and laminate form, that can be integrated into a number of filter housing systems. These media enable what tests show to be the highest-performing filters in the microelectronics industry today.

- sealing solutions, like sheet gasketing, pipe gaskets, gasket tape and the GORE® Joint Sealant. Each is 100% ePTFE for the utmost in creep and cold flow resistance, so they'll stay in place to keep processes contained.

For over 35 years, Gore has been a key partner to global leaders in technological innovation, providing the Gore brand of purity to processes that require it. As the industry adapts to changes in technological trends — with increasingly small smartphones and wearables requiring the smallest of semiconductors — we, too, will innovate, providing vital products and support to technology companies looking to shrink their products while growing their profits.

Contact Us

UK

+44 1382 56 1511

+44 1382 56 1007 (fax)

United States

+1 800 356 4622

Germany

+49 9144 6010

+49 9144 6816 (fax)

Italy

+39 045 6209 209

+39 045 6209 165 (fax)

France

+33 1 5695 6565

+33 1 5695 6401 (fax)

Spain

+34 93 480 6900

+34 93 373 7850 (fax)

Sweden

+46 31 7067800

+46 31 864226 (fax)

China (Beijing)

+86 10 5707 4999

+86 10 5707 4900 (fax)

China (Shanghai)

+86 21 5172 8299

+86 21 6247 9199 (fax)

China (Shenzhen)

+86 755 8359 8262

+86 755 8359 1654 (fax)

South Korea

+82 2 393 3411

+82 2 393 1285 (fax)

Japan

+81 3 6746 2582

+81 3 6746 2571 (fax)

Resources

Technical Information: The Evolution of GORE® Trackless Cable

Technical Information