GORE® Tethered Drone Cables for Commercial & Defense

Fly higher, see farther and do more with Gore’s durable, low-weight hybrid solution. Our cables give you more payload options, allow drones to fly higher and expand your line of sight or coverage. Built with high-strength and weather-proof materials, they’re proven to last longer in challenging conditions than standard cables.

Contact Us

+1 800 626 7708

Germany

+49 9144 6010

+49 9144 6816 (fax)

UK

+44 1382 56 1511

+44 1382 56 1007 (fax)

Italy

+39 045 6209 209

+39 045 6209 165 (fax)

France

+33 1 5695 6565

+33 1 5695 6401 (fax)

Spain

+34 93 480 6900

+34 93 373 7850 (fax)

Sweden

+46 31 7067800

+46 31 864226 (fax)

China (Beijing)

+86 10 5707 4999

+86 10 5707 4900 (fax)

China (Shanghai)

+86 21 5172 8299

+86 21 6247 9199 (fax)

China (Shenzhen)

+86 755 8359 8262

+86 755 8359 1654 (fax)

South Korea

+82 2 393 3411

+82 2 393 1285 (fax)

Japan

+81 3 6746 2582

+81 3 6746 2571 (fax)

Overview

Don't Let Your Tether Hold You Down!

Cables attached to commercial and defense tethered drones use traditional durable materials that are bulky and heavy, often weighing drones down. On the flip side, lighter-weight cable materials absorb moisture and lack enough protection to resist harsh environments like high temperatures. Both cable materials create issues during operation that can limit your payload options and reduce your drone’s capabilities.

Cables attached to commercial and defense tethered drones use traditional durable materials that are bulky and heavy, often weighing drones down. On the flip side, lighter-weight cable materials absorb moisture and lack enough protection to resist harsh environments like high temperatures. Both cable materials create issues during operation that can limit your payload options and reduce your drone’s capabilities.

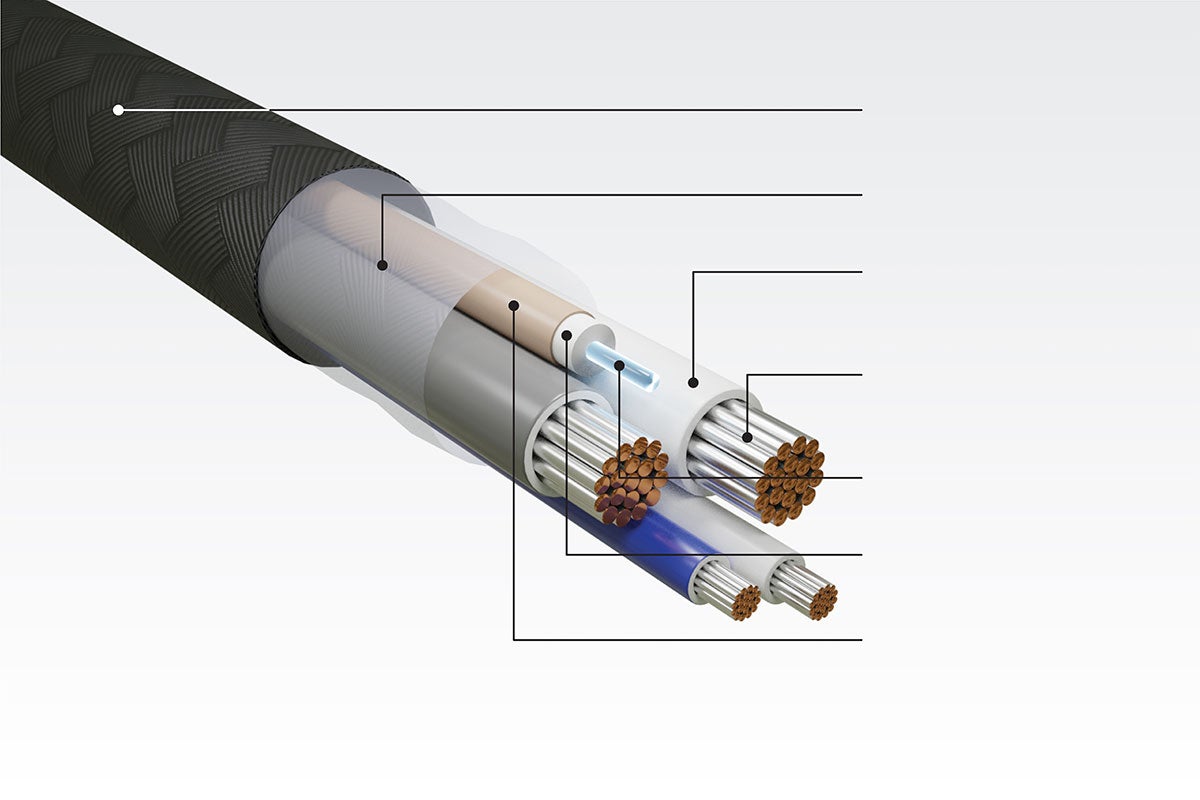

GORE Tethered Drone Cables are a game-changer for the commercial and defense industries. We strike a balance by blending reliable high-power and fiber optic cables with rugged materials in a small-scale hybrid design.

Smaller Design With Better Protection

Our tethered drone cables are 20% smaller in size than standard nylon-built cables, which means they’re naturally lighter weight. So they take up less space inside the tether management system (TMS), giving you more design options and allowing for extra payload during operation.

We also build our cables with high-strength, weather-proof GORE® Abrasion Resistant Cable Jacket. They’re proven to survive damage from abrasion, wide temperatures, humidity and repeated reeling, to name a few. In fact, our single-mode fiber optic cable offers a high level of crush resistance and meets ARINC 802-3 requirements for a secure data link from the drone to ground support equipment (GSE).

More Weight Stability In Harsh Fluids

Because every gram of weight saved on a drone matters, we tested our unique fiber braid cable against a standard nylon cable to see how both performed when immersed in harsh fluids. Results showed that the initial weight of the nylon cable increased significantly by 13% in hydraulic fluid and more than 7.5% in salt water. But, our cable offers 90% less weight pickup, particularly holding less than 1% in saltwater for even more design/payload options and height above ground level (AGL).

High-Strength, Lightweight Construction of GORE Tethered Drone Cables.

Applications

With proven unrivaled durable performance, GORE Tethered Drone Cables deliver unfailing data transmission, secure signals and high-voltage power in applications like:

- electro-optical infrared (EO/IR) sensors

- HD streaming camera & video systems

- intelligence, surveillance & reconnaissance (ISR)

- Search & rescue operations

- Telecommunications

The fiber can also function as a reliable low-loss coaxial cable for applications that transmit and receive data like:

- line-of-sight communication

- mesh drone networks

- rural network connectivity

- temporary cell towers

- video streaming (downlink for emergency response, search & rescue, aerial photography, news & events, border patrol)

Features & Benefits

Outperforming standard cables, GORE Tethered Drone Cables bring unique features that give them more durability against harsh environments and contaminants, including:

- crush- and abrasion-resistant materials

- chemically inert, weather-proof materials

- low-friction fiber braid cable jacket

- smaller, lighter weight cable diameters

For system architects and engineers, our hybrid cables offer numerous benefits that enable drones to fly higher, see farther and do more, like:

- more design options and extra payload with reduced size/weight

- less weight pickup for more stability in harsh fluids than nylon cables

- withstand abrasion, weather, terrain, extreme temperatures, repeated reeling, more

- proven crush-resistant fiber optic cable meets ARINC 802-3 requirements

- deliver continuous high-voltage power, secure signals, high-bandwidth data transfer

- easier handling, less maintenance, extended product life, fewer cable replacements

Technical Specs

These values demonstrate the electrical, mechanical and environmental performance of GORE Tethered Drone Cables for commercial and defense.

| Elec./Mech./Environ. Property | Power Pair | Data Pair | Fiber Optic |

|---|---|---|---|

| Operating Voltagea Vrms | 250 | 600 | — |

| Testing Voltage Vrms | 1500 | 1500 | — |

| Maximum Optical Loss at 1310 nm (dB/km) | — | — | 0.35 |

| Maximum Optical Loss at 1550 nm (dB/km) | — | — | 0.20 |

| Jacket Material | Engineered Fluoropolymer Fiber Braid | ||

| Jacket Color | Black | ||

| Insulation Color | Blue / White | Gray / White | Brown |

| Insulation Wall Thickness mm (in) | 0.14 (0.006) | 0.14 (0.006) | — |

| Conductor | Silver-Plated Copper | Silver-Plated Copper | — |

| Mode Type µm | — | — | Single (900) |

| Core / Cladding / Coating | — | — | 8 / 125 / 245 |

| Coating Type | — | — | High Temperature Acrylate |

| Buffer | — | — | ePTFE |

| Dielectric Material | Expanded PTFE/PTFE | ||

| Crush / Impact Resistanceb kgf/cm (lb/in) (ARINC 802-3) | — | — | Pass |

| Tensile Strengthb N (lb) 16 AWG 20 AWG 24 AWG | 1538 (345) 1092 (245) 910 (204) | ||

| Scrape Abrasionb Cycles, 500 g (1.1 lb) (SAE AS4373™) | > 36,000 | ||

| Fluid Immersion / Weight Stabilityb % Absorption (SAE AS4373™) | Pass > 1 (Salt Water, Diesel) / > 2.5 (Hydraulic) | ||

| Cold Bend Resistanceb (SAE AS4373™) | Pass | ||

| Temperature Range °C | -60 to +200 | -60 to +200 | -60 to +85c |

a Based on a NEMA HP3 wire.

b Testing based on size 22 AWG.

c Attenuation may increase above 85°C.

Videos

Watch Gore engineers in these videos and more on YouTube demonstrating the features and benefits of GORE Tethered Drone Cables.

Get Samples or Buy

Don’t waste time with standard cables tethering you down and wearing out long before the drone. Fly higher, see farther and do more with durable, low-weight GORE Tethered Drone Cables proven to outperform standard cables over the drone’s lifecycle. Confirm the quality and compatibility of our cables in your commercial or defense application by requesting a complimentary sample.

If you’re ready to order now, call one of our wire and cable distributors for in-stock availability. Or, contact us today to learn more about our hybrid solution with a patented design and talk about your specific application needs and requirements.

Resources

Data Sheet: GORE® Tethered Drone Cables for Commercial & Defense

Data Sheets, 1.23 MB

View all resources for GORE Tethered Drone Cables for Commercial & Defense

Recent News

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Contact Us

Related Products

Cables & Cable Assemblies

- Shielded Twisted Pair Cables for Defense Air & Land

- CAN Bus Cables for Defense Land Systems

- Ethernet Cables for Defense Air & Land

- Coiled Cables for Defense Land Systems

- Quad Cables for Defense Land Systems

- USB Cables for Defense Land Systems

- HDMI Cables for Defense Land Systems

- DVI Cables (Digital Only) for Defense Land Systems

- Fiber Optic Cables for Defense Air & Land

- Coaxial Cables for Defense Land Systems

- Cable Protection Systems for Defense Land Systems

- Abrasion Resistant Cable Jacket for Defense Land Systems

Follow GORE® Tethered Drone Cables for Commercial & Defense